Steel cutting discs are indispensable tools in metalworking, construction, and various industrial applications. Their ability to cut through steel and other hard materials efficiently makes them a preferred choice among professionals and DIY enthusiasts alike. However, improper use of these tools can lead to inefficiencies, safety hazards, and suboptimal results. In this article, we will explore the top 10 mistakes to avoid when using steel cutting discs, ensuring that your work remains safe, efficient, and cost-effective.

Choosing the Wrong Type of Disc

One of the most common errors when using steel cutting discs is selecting the wrong type for the job. Steel cutting discs come in various sizes, thicknesses, and material compositions, each designed for specific applications. Using a disc that is not designed for cutting steel, or one that is too thin or thick for the material at hand, can result in poor performance, increased wear, and potential safety risks.

Before starting any project, it is essential to consult the manufacturer’s guidelines or seek expert advice on the appropriate disc for the task. For example, thinner discs are typically used for precision cuts, while thicker discs are better suited for heavy-duty cutting. In Dubai and the UAE, where construction projects often involve high-strength steel, using the correct disc type is crucial to ensure both efficiency and safety.

Neglecting Safety Precautions

Safety should be the top priority when working with steel cutting discs. Unfortunately, many users overlook basic safety precautions, leading to accidents and injuries. Common safety mistakes include not wearing appropriate protective gear, such as safety goggles, gloves, and ear protection, and failing to secure the workpiece properly.

In the UAE, where safety regulations in the construction and industrial sectors are stringent, compliance with safety standards is non-negotiable. Always ensure that the work area is well-ventilated, free of flammable materials, and equipped with fire extinguishers. Additionally, operators should be trained in the correct use of steel cutting discs and aware of emergency procedures.

Improper Mounting of the Disc

Incorrect mounting of the steel cutting disc on the power tool is another frequent mistake that can compromise performance and safety. The disc must be securely attached to the tool’s spindle, with the correct flange and nut tension. Over-tightening can cause the disc to crack, while under-tightening can lead to slippage during operation.

To avoid these issues, always follow the tool manufacturer’s instructions for mounting the disc. In professional settings, such as construction sites in Dubai, where multiple workers may use the same tools, regular inspections of the mounting setup are necessary to prevent accidents.

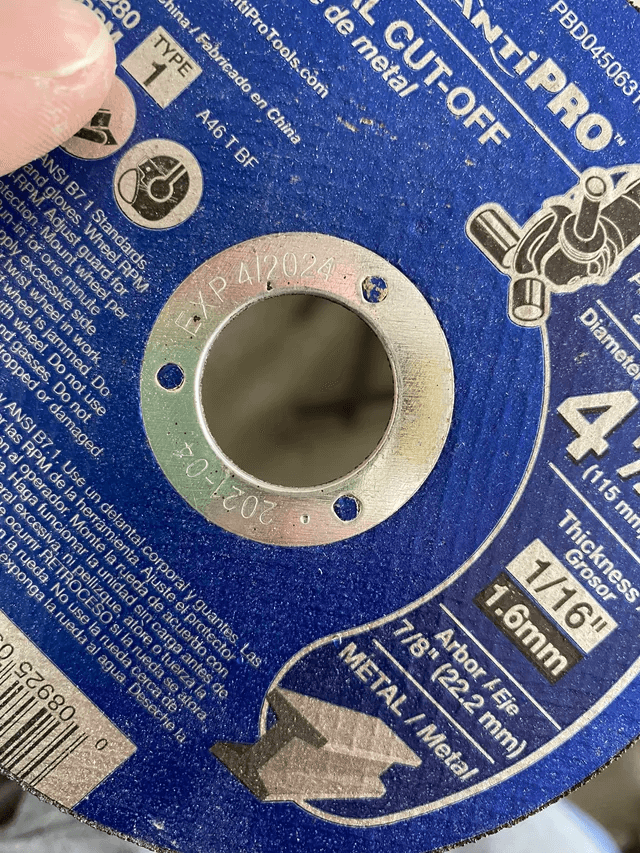

Using Damaged or Worn-Out Discs

Using a steel cutting disc that is damaged or excessively worn out is a dangerous practice that can lead to disc failure during operation. Discs that have cracks, chips, or are excessively thin should be discarded immediately. Continuing to use a compromised disc not only affects the quality of the cut but also poses a significant risk of injury.

It is advisable to inspect discs before each use and replace them if any signs of damage are detected. In the UAE, where the climate can cause rapid wear on cutting tools due to high temperatures and humidity, regular checks are even more critical to ensure safe and efficient operation.

Incorrect Cutting Techniques

The technique used when cutting steel with a disc is crucial for achieving a clean cut and prolonging the life of the disc. A common mistake is applying excessive pressure or using the disc at an incorrect angle. Both practices can cause the disc to overheat, wear out prematurely, or even shatter.

When using a steel cutting disc, it is important to maintain a steady hand, keep the tool at the recommended angle (usually around 90 degrees), and let the disc do the work without applying too much force. In environments like Dubai’s construction sector, where precision and efficiency are paramount, mastering the correct cutting technique is essential.

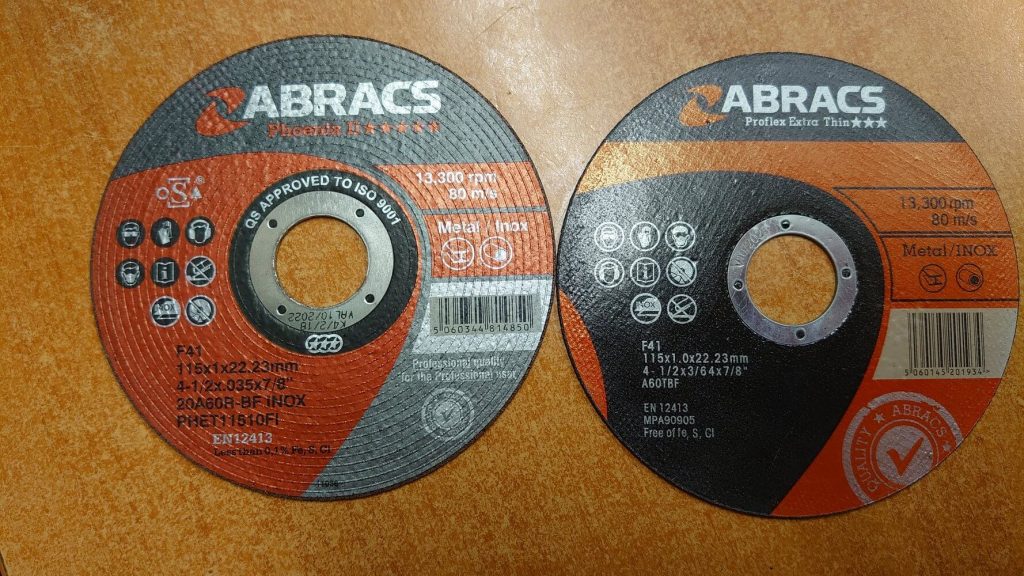

Ignoring Disc Speed Ratings

Each steel cutting disc is designed to operate at a specific maximum speed, usually measured in revolutions per minute (RPM). Exceeding this speed rating can cause the disc to disintegrate, leading to potentially severe injuries. Users often make the mistake of disregarding the speed rating, either due to a lack of awareness or in an attempt to speed up the cutting process.

To avoid this mistake, always check the disc’s speed rating and ensure that the power tool is set to operate within this limit. In the UAE, where construction projects are often conducted under tight deadlines, it is tempting to push equipment beyond its limits. However, safety must always take precedence over speed.

Using the Wrong Tool for the Disc

Another common error is using a steel cutting disc with a tool that is not designed for it. For instance, attaching a cutting disc to a tool meant for grinding can lead to suboptimal performance and increased risk of accidents. Each tool is designed with specific functions in mind, and using the wrong tool-disc combination can result in tool damage and unsafe working conditions.

Always ensure that the power tool is compatible with the type of steel cutting disc being used. In professional environments, like those in Dubai’s booming construction industry, using the right equipment is key to maintaining both efficiency and safety on the job site.

Failing to Perform Regular Maintenance

Regular maintenance of both the cutting disc and the power tool is essential to ensure optimal performance and safety. A common mistake is neglecting maintenance tasks such as cleaning the tool, inspecting the disc for wear, and replacing worn-out parts. Lack of maintenance can lead to tool malfunctions, reduced cutting efficiency, and increased safety risks.

Implementing a routine maintenance schedule is crucial, particularly in regions like Dubai, where environmental factors such as dust and heat can accelerate wear and tear on equipment. Regularly checking the tool’s components, lubricating moving parts, and replacing worn discs can significantly extend the lifespan of the equipment and improve safety.

Overlooking Environmental Factors

Environmental conditions play a significant role in the performance and safety of steel cutting discs. In the UAE, where high temperatures, dust, and humidity are common, failing to account for these factors can lead to disc degradation and safety hazards. For example, using a disc in extreme heat can cause it to overheat, while dust accumulation can impair visibility and accuracy.

To mitigate these risks, always consider the environmental conditions before starting a cutting project. In Dubai, where construction often takes place outdoors, using appropriate protective gear, maintaining a clean work area, and selecting discs designed to withstand harsh conditions are critical steps in ensuring safe and efficient operations.

Disregarding Manufacturer’s Instructions

Finally, one of the most overlooked mistakes is failing to follow the manufacturer’s instructions for using steel cutting discs. These guidelines are provided to ensure the tool’s safe and effective operation. Ignoring them can lead to a range of issues, from suboptimal cutting performance to serious safety hazards.

In Dubai’s construction industry, where efficiency and safety are paramount, adhering to the manufacturer’s instructions is essential. Whether it’s regarding disc selection, tool operation, or maintenance practices, following these guidelines can prevent accidents and ensure that the project is completed on time and within budget.

Conclusion

Avoiding these common mistakes when using steel cutting discs can significantly improve both the quality of your work and your safety on the job. By selecting the right disc, following proper safety protocols, and maintaining your tools, you can ensure efficient and effective cutting operations. In a region like Dubai, where the demand for high-quality construction and industrial work is ever-growing, using steel cutting discs correctly is crucial for achieving professional results.

For those in the UAE looking for high-quality steel cutting discs and related products, Middle East Fuji Industrial Solutions offers a wide range of options tailored to the needs of the region’s construction and industrial sectors. By choosing the right products and following best practices, you can enhance your project’s success and maintain a safe working environment.

Skydiver, shiba-inu lover, music blogger, vintage furniture lover and collaborator. Performing at the crossroads of aesthetics and purpose to express ideas through design. Let’s chat.